centrifuge decanter|decanter centrifuge manufacturer : supermarket Introduction to Decanter Centrifuges Decanter centrifuges have carved a niche in .

{plog:ftitle_list}

Autoclaves are used in education, research, biomedical research, pharmaceutical research and industrial settings to sterilize lab instruments and glassware, process waste loads prior to disposal, prepare culture media and liquid media, and artificially age materials for testing. Although autoclaves produced for use in medicine may be used in research settings, labs may opt for "research-grade" autoclaves. These are specifically designed for non-medical applications. .

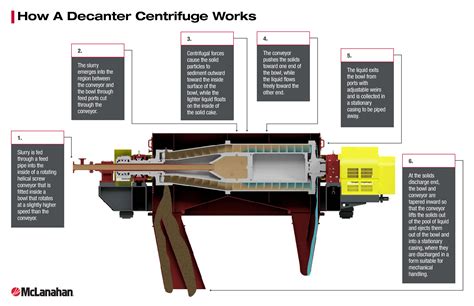

Introduction to Decanter Centrifuges Decanter centrifuges have carved a niche in .the decanter centrifuge was therefore to provide the continuous mechanical separation of liquids from solids, to keep pace with modern industrial demands. In essence, a centrifuge is a clarifier whose base is wrapped around a 4 Alfa Laval – decanter centrifuge technology Working principles Continuous separation Virtually all branches of .Decanter Centrifuge consists of a bowl rotating at high rpm in horizontal axis to apply the necessary high centrifugal (G) force to provide solid-liquid separation, a spiral conveyor rotating with the bowl at acertain differential speed, a driving group that provides the necessary force to these rotating parts and the chassis (body) that .A decanter centrifuge, also known as a horizontal bowl centrifuge, solid bowl centrifuge or scroll centrifuge, is a machine used to separate a solid material from a liquid(s) using a high-speed and continual rotational process.

FLSmidth’s Decanter brand has earned its proud reputation throughout 20 years of serving the centrifuge industry. Decanter centrifuges and services are found on 6 conti-nents. No matter where a customer is located, no matter what the application, FLSmidth is ready to provide the very best Decanter products, parts and services available.

Decanter Centrifuge Structure and Key Components Display. Decanter centrifuge consists of multiple components, including the main motor drive system, auxiliary motor, differential, screw conveyor, drum, protective cover, base, damping system, main bearing housing, lubrication system, etc. ZK SEPARATION is dedicated to maintaining strict quality control over product .The Disc Centrifuge generates a much higher G-force than Decanter Centrifuges. Other differences between Decanter Centrifuges and Disc Centrifuges include the footprint, power requirement, separation efficiency and allowable feed solids. Decanter Centrifuges are ideal for slurries with high solids content and large particle sizes.

Flottweg decanter centrifuges are used in a wide variety of processes. Due to the wide range of applications, it is necessary to adapt the decanter centrifuge with appropriate wear protection to the respective conditions and requirements. Flottweg offers various types of wear protection to reduce wear and keep abrasion to a minimum.SWECO's 414 and 518 high speed, decanter centrifuges deliver high recovery rates and efficient solids separation to significantly reduce disposal costs or reclaim valuable material from process streams. The SWECO 414 and 518 centrifuges are precision-balanced for smooth operation over long periods at high RPM speeds, generating extremely high G . The centrifuge decanter has substantial equipment expenses. Hard surfacing and abrasion protection materials are required for the scroll in order to prevent wear and, consequently, maintenance. What is the difference between centrifuge and decanter?3-Phase Separating Decanter. The 3-Phase Separating Decanter is a centrifuge in which two liquids of different densities are separated from each other. At the same time solids are separated and discharged.

screw press vs decanter centrifuge

The ALDEC G3 decanter is built around the Slimline design – a breakthrough in decanter centrifuge performance and capabilities. The smaller conveyor diameter makes room for more liquid in the pond, and allows higher bowl wall pressures, resulting in .For more than 15 years Allcentrifuges has been developing and producing high-performance decanter centrifuges, separators, belt presses and plants for solid-liquid separation. Hand in hand with our customers, we are always prepared to meet new challenges and develop goal-oriented solutions. The ultimate goal is always clear: the success of our .The decanter centrifuge has become a major processing tool in a wide range of liquid/solid separation applications. The solid-bowl scroll-discharge centrifuge (now almost universally known as the decanter centrifuge) is considered as the workhorse of a wide range of liquid/solid separation activities. Its application to the dewatering of waste .

A decanter centrifuge operates on the fundamental principle of gravitational separation, where the theory of gravity is harnessed to achieve effective separation. It employs a high-speed rotational process to achieve efficient liquid-solid separation, making it indispensable in wastewater treatment, chemical processing, oil refining, and food .Decanter centrifuges are to be found in all types of industries for a multitude of separation applications. This post describes some of the decanter centrifuge applications Dolphin has supplied for. +1 (248) 522-2573 [email protected] 24248 Gibson Dr., .These vertical decanter centrifuges, also called centrifugal decanters, batch decanters, or solid bowl centrifuges, have been furnished to fine chemical and pharmaceutical producers worldwide, and include the following features: Fully opening cover for easy maintenance;Available as single decanter centrifuges, skid-mounted units and complete plants, the ANDRITZ decanter centrifuge range includes both ATEX Zone 1 and Zone 2 machines. This makes them suitable for use in plants where an explosive atmosphere may occur during normal operations.

2 Benefits of Modern Decanter Centrifuges ∙ Optimum separation efficiency ∙ Small footprint ∙ Sealed construction to control odor emissions and avoid contamination of the product ∙ Ease of operation due to continuous and automatic operation ∙ Limited consumables such as filter media or filter aids In many processes, mechanical separation has a decisive influence on product

Alfa Laval separators and decanter centrifuges are equipped with precise control mechanisms to adjust factors like rotational speed and fluid flow, allowing for the accurate separation of different materials. This technology is widely employed in industries such as wastewater treatment, food and beverage, pharmaceuticals and oil refining .

A decanter centrifuge is a high-performance mechanical device designed to separate solids from slurries, commonly used in industrial applications like oil well drilling. In this process, centrifuges help to condition drilling fluids by separating them into high-density and low-density streams through accelerated sedimentation. As the fluid . Decanter centrifuges with the same diameter but a longer length would have a higher capacity for conveying solids and a larger suspension volume, which would improve fine solid settling. The beach angle at the conical section of a decanter centrifuge is a design heuristic that must be considered as well. When solids exit the pool onto the beach .

describe autoclaving process

https://materiais.gratt.com.br/decanter_centrifugoCentrifugal decanter for two-phase separationThe constant improvements and refinements developed by our tea. Flottweg decanter centrifuges are used for continuous separation of suspended solids from liquids, clarification of solids, classification of fine pigments, .30 Second Summary Takeaway. Decanter centrifuge performance optimization involves tuning or adjusting specific operating parameters to improve the separation efficiency of the decanter.. In this article, we discuss the 5 most effective and straightforward ways to .

describe the use of an autoclave in microbiology laboratory

Continuous decanter centrifuges are most typically used for processes in which continuous production is required, such as purifying used lubricating oils. Corn used to make ethanol is shown below, to the left. Ethanol producers use centrifuges in the production of ethanol from corn. The picture to the right is an example of an industrial pusher . Alfa Laval decanter centrifuges help you with solid-liquid separation within one single continuous process. Stand out from the competition with high performance separation that results in extracted / clarified products of excellent quality and higher commercial value. Make a difference as you recover valuable raw materials, reduce energy .How a decanter centrifuge separates solids. Liquids of different densities or solutions with solids, which are denser than liquids, are the best candidates for centrifuge clarification. Also known as a solid bowl centrifuge or horizontal bowl centrifuge, a decanter centrifuge is commonly used in various industrial processes.

difference between decanter and centrifuge

decanter centrifuge price

WA Autoclaves is your one-stop-shop for sales, service and repair of bench top autoclaves.The latest Warzone patch notes, released by Raven Software on December 10, 2024 (US time), bring a significant improvement to Ranked Play aimed at maintaining a fair battlefield for all players.. Additionally, the update .

centrifuge decanter|decanter centrifuge manufacturer